EVERYTHING FOR PLANES AND PILOTS SINCE 1965 | 877-4-SPRUCE

- JUMP TO

- Overview

- Accessories

- Reviews

- Q&A

Overview

|

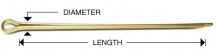

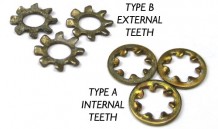

A-Spec fasteners are common to Beechcraft airplanes and latches on many cowlings. The design consists of a simple stud, with a pin pressed into the shank. The pin is installed after inserting the stud through the panel hole and removed prior to removing the stud. Some installations use a grommet in the fastener hole. Unlike other fasteners, the grommet does not usually require replacement when installing new studs. Base part numbers indicate stud diameter and head style. A-Spec studs are made in several blank lengths indicated by the first dash number in the charts. Each blank length can have up to 10 second dash numbers or grip sizes. The second dash number indicates the maximum grip range in .010² increments. Milspec primarily stocks sizes common to Beech aircraft in stainless steel for repacement purposes. To remove an A-Spec stud, simply clip or remove the pin enough to back the stud out of the hole. New pins are pressed in using special pliers, or by modifying standard vice grip pliers. Drill or cut one jaw of the vice grip to allow proper relief for the pin. If new grommets are required, a flaring tool is necessary (see below). |

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.