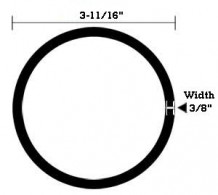

Tempest Prop Governor Gasket

MFR Model# AA9144

- JUMP TO

- Overview

- Reviews

- Q&A

- View in Catalog

Overview

|

The Tempest gaskets are fully compliant wlth all FAA test requirements. They are certified for use on all reciprocating engines that formerly used MS or AN type governor gaskets. In Tempest tradition, the design of the gaskets is an improvement over MS gaskets. They are successfully tested to withstand 1000 psi. A 20% increase over the MS test requirements. Factory applied DC4 lubricant to prevent gasket from stlcking to engine or governor. The specialized black coats on the stainless steel screen whlch Is "vulcanizd" between the outer layers of the Buna N rubber makes the gasket "monolithic" In construction. The rubber cures Into a solid block wlth the screen trapped Inslde it. This special process is designed to eliminate leaks that can occur with the laminated dle cut gaskets. McCauley: B-20024 Woodward: 2092 17 Hamilton Standard: 57354 MS: MS 100009 MS: MS9 144 Cessna: 53108. TCM (Continental): 531083 |

Q&A

Please note, Aircraft Spruce's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Please refer to your engine parts manual to determine application requirements. This can be used on a variety of engines.

FREE Shipping

FREE Shipping